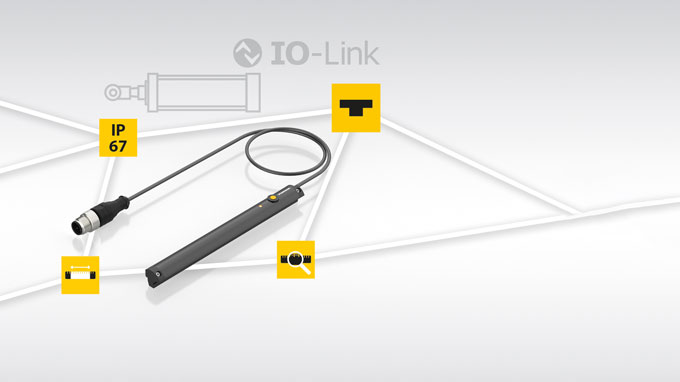

Turck's new WIM-IOL series can detect cylinder movements precisely, from 32 to 256 mm

Magnetic Position Sensors with IO-Link

Turck's new WIM-IOL series offers compact magnetic field sensors with digital interface for measuring ranges from 32 mm to 256 mm

Turck has extended its offering of compact position sensors with the WIM-IOL series for detecting magnetic pistons in pneumatic or hydraulic cylinders. The new series consists of eight sensors with IO-Link 1.1, covering measuring ranges from 32 mm to 256 mm. IO-Link and the integrated pushbutton enable users to teach the measuring range of sensors quickly and conveniently to the stroke of the pistons in the cylinder. This simplifies mounting compared to analog sensors, as these have to be fitted either exactly to the dead points or operate with correction factors in the controller. The IP67 sensors operate with a 15-bit resolution.

Your Benefits

- Cost saving through short commissioning times

- Variants to match different cylinder lengths

- Adaptable for any application

- Data supplier for Industry 4.0

Typical applications include feed detection in injection molding machines or automatic screwing machines, the positioning of the welding head with ultrasonic welding or the monitoring the foil tension in packaging machines.

INDUSTRIES

- Plastics Processing

- Automotive

KEY FUNCTIONS

- Eight variants for measuring ranges from 32 mm to 256 mm

- IO-Link 1.1

- Fast and easy mounting from above

RELATED CONTENT

At a Glance: Process Optimization with IO-Link

IO-Link is essential for paving the way for efficient, digital production

Technology Page: For Those Who Want to Know More

Technical background information on the IO-Link communication standard

PRODUCT DATA

All Details about the WIM-IOL Magnetic Position Sensors

Approvals, data sheets, technical specifications, instructions, certificates, CAD data and more