Industrial Cloud

Cloud Solutions for Industrial Applications

Cloud solutions provide flexible access to storage, computing power or software. Data is not stored on the local IT hardware, but on servers. This allows users to access information or initiate actions from different web-enabled devices, regardless of location and time.

Unlike business or private clouds, industrial clouds are highly specialized. They need to address vertical integration within specific industries, support standardized communication protocols with bidirectional information flow and meet high security requirements.

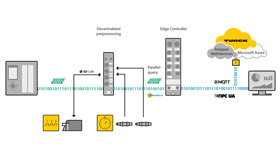

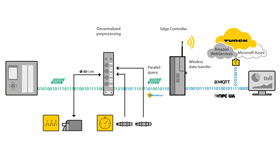

Data preprocessing in edge controllers

In order to process data from machines and sensors specifically in the cloud, filtering in the edge, i.e. at the "outer edge" of a local network, is an important process. In edge controllers, users can define which information should be transferred to the cloud and which should remain in the OT environment instead. This reduces the data density on the servers.

Via cable, WLAN or mobile communication

Communication from field level to the cloud can take different paths. In addition to the option of connecting applications via mobile radio, existing Internet access points at the location can be used either wired or via WLAN. Future-proof standard protocols are OPC UA and MQTT, allowing components alongside Turck Cloud Solutions to be integrated into various clouds such as MS Azure, Alibaba or Amazon Web Services.

Edge controllers with wireless interface enable data transfer to the cloud via WLAN or the mobile network

Individual data storage

Many companies want to determine the location of data hosting individually. With Turck Cloud Solutions, users can therefore choose to use either the infrastructure of large data centers or their own IT capacities. "Software as a Service" (SaaS) provides the system performance and 24/7 support of professional data centers with a selectable server location. In the “Platform as a Service” (PaaS) variant, the cloud instead is hosted on the company's own servers. A private cloud like this does not necessarily have to be connected to the Internet.

Cloud dashboard — flexible user interface

Current machine data and states are visualized on a dashboard such as the Turck Cloud Portal. This also allows users to perform various settings and, for example, set a notification via e-mail or SMS in case of a threshold being exceeded. The interface can be individually adapted and, if desired, styled in its own corporate design.

Video: Data Transfer from the Sensor to the Cloud

Turck's end-to-end IIoT infrastructure enables users to digitize their production and logistics processes. See where Turck's edge controllers with smart preprocessing ensure efficient data communication.

Video: Data Transfer from the Sensor to the Cloud

Fields of application

End-to-end communication between sensors and the cloud is the basis for an efficient Industrial Internet of Things (IIoT). Combined with the advantages of the digital standard IO-Link, this opens up a wide range of applications.

Condition & environment monitoring

- Keep track of condition data for machines and plants around the clock

- Predict anomalies remotely in the edge controller and send to the cloud

- Receive critical condition notifications

Process management in the cloud

- Simulate processes in the system's digital twin

- Worldwide remote machine control

- Trigger automatic processes in ERP, for example repeat orders

Remote services

- Remote access to devices and machines thanks to bidirectional communication

- Parameterization and maintenance without on-site inspection

- Reports for manufacturers and users

Further Information

- At a Glance: Seamless Data Communication Between Sensor and Cloud

- Webinar Recording – Cloud Solutions: Bidirectional Cloud Solution for Industrial Automation

- Flyer – Turck Cloud Solutions: Cloud Solutions for Industrial Applications

- Product News – TBEN-L-PLC: IP67 PLC and Edge Gateway in One Device

- Product News – TX700: Robust HMI/PLC with IIoT Gateway for Food Industry and Outdoor Areas

- Topics & Technologies

- Asset Monitoring Gateway with Cloud ID

- Asset Monitoring Gateway with SNAP ID

- Codesys

- Condition Monitoring

- Ethernet in Hazardous Locations

- Field Logic Controller

- Industrial Cloud

- Industry 4.0

- IO-Link

- Machine Safety

- Modular Machines

- Module Type Package

- Multiprotocol Ethernet

- Pick-to-Light

- Profinet

- RFID

- Safe work and Occupancy Monitoring

- Snap Signal

- Sustainability

- TAS – IIoT Service Platform

- The Visual Factory